Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: ZL-8

Brand: Sihai

Function: Oil Boiler

Fuel: Oil-Fired

Installation: Assembled Boiler

Structure: Water Tube

Media: Steam

Water Circulation: Mixed Circulation

Drum Placement: Horizontal Boiler

Pressure: Low Pressure

Manufacturing Level: A

Burning Style: Chamber Combustion Boiler

Usage: Industrial

Cooling Method: Water Cooling

Reactor Size: 2000*6000mm

Handling Capacity: 10 Tons

Working Form: Vacuum/negative Pressure

Working Mode: Continuous Working

Life Span: 5~8 Years

Operation Labor Needed: 1~2 Person

Raw Material Catagory: Waste Engine Oil/ Crude Oil//plastic Oil/ Tyre Oil Etc

Application: Used Engine Oil Refining To Diesel Oil Plant

Packaging: seaworthy packing in containers

Productivity: 200 sets/year

Transportation: Ocean

Place of Origin: Henan

Supply Ability: 200 sets/year

Certificate: ISO CE

HS Code: 8419409090

Port: Lianyungang,Qingdao

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CIF

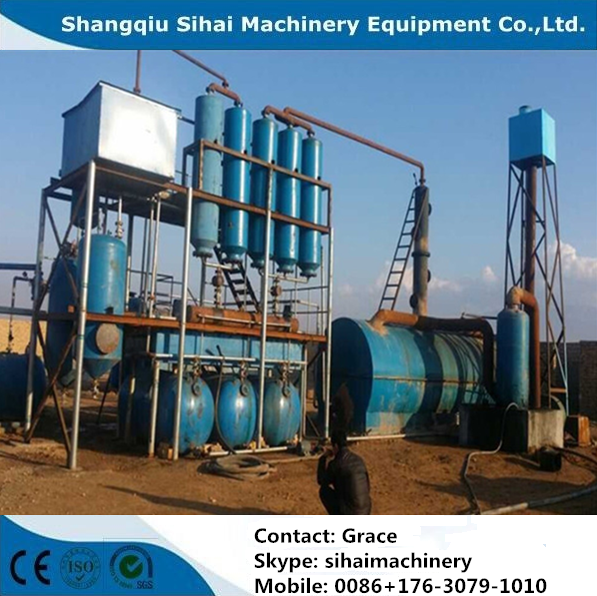

used engine oil refining to diesel oil plant

1. Materials can be used in the used engine oil refining to diesel oil plant:

a. Waste oil .example: waste diesel, waste oil residue etc.

b. tire/rubber oil

c. plastic oil

d. crude oil

e. waste engine oil

f. waste motor oil

g. waste lube oil

h. waste transformer oil

i. underground oil

2. Production introduction:

used engine oil refining to diesel oil plant is the new technology which can refine the tire oil , plastic oil , waste engine oil, sludge, motor oil and so on into base oil(which can be made into diesel and gasoline after processed by our catalyst). The oil quality is better than the original normal pressure distillation technology, which show on purity ,transparence, lightness. This technology will do deodorization and destinke process to the raw material oil automatically by "dry type" vacuum pressure distillation method. With the vacuum distillation technology, the distillation temperature is considerably reduced, and the oil output will higher 5%-10% compared with original normal pressure distillation technology. It makes more profits to the enterprise virtually.

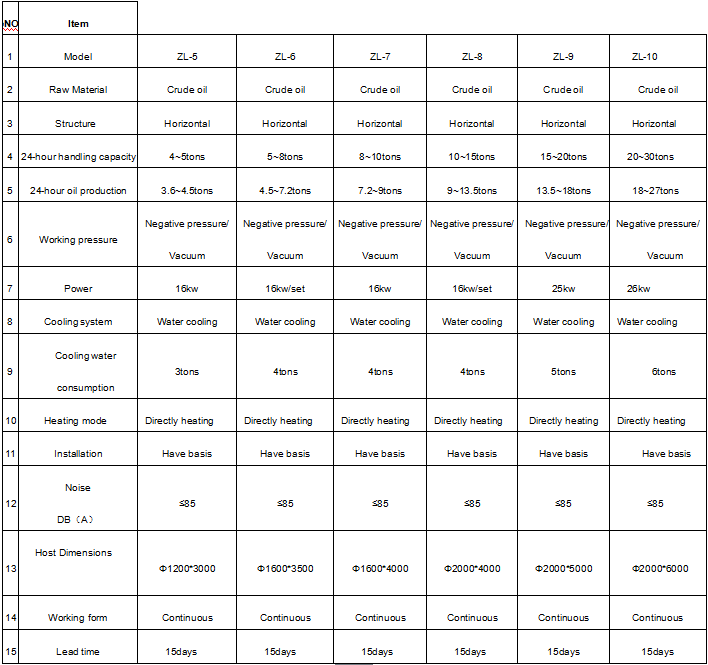

3. Models of the used engine oil refining to diesel oil plant:

4. The comparison between the index of diesel, mixed oil after distillation and international standard 0# diesel:

| Item | Diesel (after distillation) | Mixed oil | international standard 0# diesel |

| oxidation stability | 2.0 | 1.5 | 2.5 |

| sulfur content % | 0.07 | 0.06 | 0.05 |

| ash content % | 0.035 | 0.03 | 0.02 |

| copper corrosion /rank | 1.1 | 1.1 | 1 |

| Water content% | mark | mark | mark |

| mechanical impurity | no | no | no |

| density | 0.87 | 0.85 | 0.82-0.86 |

| Solidifying point /℃ | -10 | -10 | 0 |

| flashing point (close)/℃ | 45 | 40 | 55 |

| Kinetic viscosity | 2.92 | 2.9 | 2.7-3.0 |

| Combustion value KJ/ kg | 9500 | 9200 | 8500 |

| cetane ratio | 43 | 40 | 46 |

Product Categories : Waste Oil Distillation Plant > Waste Engine Oil Distillation Plant

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.