Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LJ-10

Brand: SIHAI

Warranty: 1 Year

Certification: CE ISO SGS

Service Life: <15 Years

Voltage: 380V

Structure: Horizontal

Cooling System: Water Cooling

Heating Method: Direct Heating

Material: Q245R Boiler Steel

Oil Output Rate: 45%

Area Required: 300 Square Meter

Installation: Free Of Charge

Reactor Size: 2600*6600mm

Handling Capacity Tons: 10 Tons

Packaging: Seaworthy packing

Productivity: 200SETS/YEAR

Transportation: Ocean

Place of Origin: HENAN

Supply Ability: 200SETS/YEAR

Certificate: CE ISO

HS Code: 8419409090

Port: Lianyungang,Qingdao,Shanghai

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CIF

Newly designed Waste Tire Recycling to oil plant

Background Introduction of this project:

As the automotive industry is growing in large scale widely all over the world, more and more cars are being produced every year in all countries to meet up with the car markets' needs. In the meantime, with the rapid development of car industries, pollution of the waste tires has been putting forward and waste rubber has become a big environmental problem for the public.

To solve the waste rubber issue, we highly recommend the Newly designed waste tire recycling to oil plant which can recycle the waste rubbers into renewable energy like fuel oil.

1. Model of Newly designed waste tire recycling to oil plantt:

| Model | Reactor size | Material | Handling capacity | Weight | Seaworthy packing |

| LJ-8 | 2200*6000mm | Q245R boiler steel plate | 5 tons | 24tons | 2*40HQ |

| LJ-9 | 2200*6600mm | Q245R boiler steel plate | 8tons | 26tons | 2*40HQ |

| LJ-10 | 2600*6600mm | Q245R boiler steel plate | 10tons | 30tons | 1*40FR+1*40HQ |

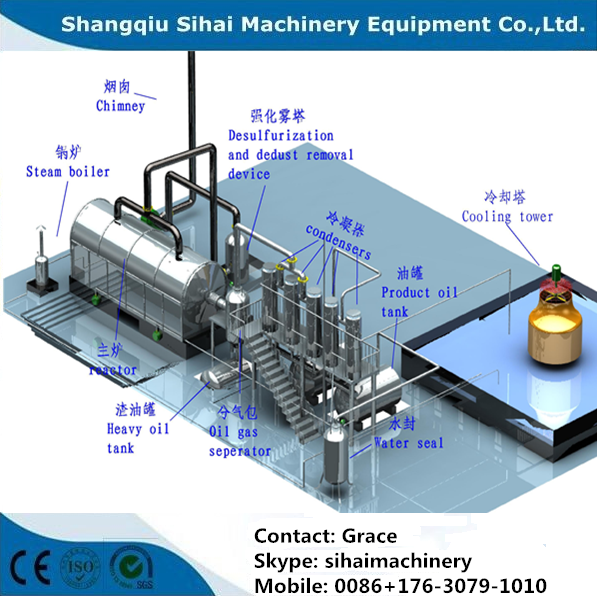

2. Working process Of Newly designed waste tire recycling to oil plant:

First, the raw materials are put into the reactor, and then seal the feeding in door, later start the machine and the reactor will be rotating and heated by coal, natural gas, wood or electricity. When the temperature reaches the degree of 250 to 280, we will get the crude oil, the oil steam will be continuous produced until the temperature reaches 350-460°C; oil steam will flow through oil gas separator, light component will enter the condensers and meanwhile the heavy oil will be discharged automatically into in heavy oil tank. The liquefied part will be condensed as crude oil, and the part which cannot be liquefied will be transferred by the water seal back to the burning chamber to be reused as heating material.

3. End of Product from Newly designed waste tire recycling to oil plant:

NO. Name Percentage Usage 1 Tyre oil 40%~45% * can be sold directly as fuel. * can be refine to diesel and gasoline by Oil Distillation Plant 2 Carbon black 37% * can be sold directly. * can be refined by carbon black processing machine to make it finer (1500mesh finer). *can be made into pellet by pellet machine 3 Steel wire 13% *can be sold directly as steel or iron. 4 Waste gas 5% * can be recycled to heat up the reactor

4. Installation: We will be in charge of arranging our engineer to go to your place to guide the installation and train your workers how to operate the Newly designed waste tire recycling to oil plant.

5. Land requirement: 300sq meters(10m*30m)

Product Categories : Waste Tire Pyrolysis Plant

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.