Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LJ-10

Brand: SIHAI

Warranty: Life Long

Cooling System: Water Cooling

Certification: CE ISO SGS

Heating Method: Direct Heating

Material: Q245R Boiler Steel

Oil Output Rate: 45%

Area Required: 300 Square Meter

Installation: Free Of Charge

Reactor Size: 2600*6600mm

Handling Capacity Tons: 10 Tons

Packaging: Seaworthy packing

Productivity: 200SETS/YEAR

Transportation: Ocean

Place of Origin: HENAN

Supply Ability: 200SETS/YEAR

Certificate: CE ISO

HS Code: 8419409090

Port: Lianyungang,Qingdao,Shanghai

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CIF

Waste Plastic Pyrolysis Plant with 90% oil yield

Background Introduction of this project:

As plastic has been used for all other industry widely, they are playing an important role in the development of our economy, but plastic did not easy to break after being used. So they become a big pollution for our environment .Therefore it is urgent to process those waste plastic without pollution.

In addition ,as the fastest development of world economy ,the shortage of petroleum will be urgent more and more .Even the expert had stated that it will have no petroleum recover in earth after 15years later , so searchIing the new resource has became an issue which is concerned by all the countries in the world.

1. Model of waste plastic Pyrolysis Plant with 90% oil yield:

| Model | Reactor size | Material | Handling capacity | Weight | Seaworthy packing |

| LJ-8 | 2200*6000mm | Q245R boiler steel plate | 5 tons | 24tons | 2*40HQ |

| LJ-9 | 2200*6600mm | Q245R boiler steel plate | 8tons | 26tons | 2*40HQ |

| LJ-10 | 2600*6600mm | Q245R boiler steel plate | 10tons | 30tons | 1*40FR+1*40HQ |

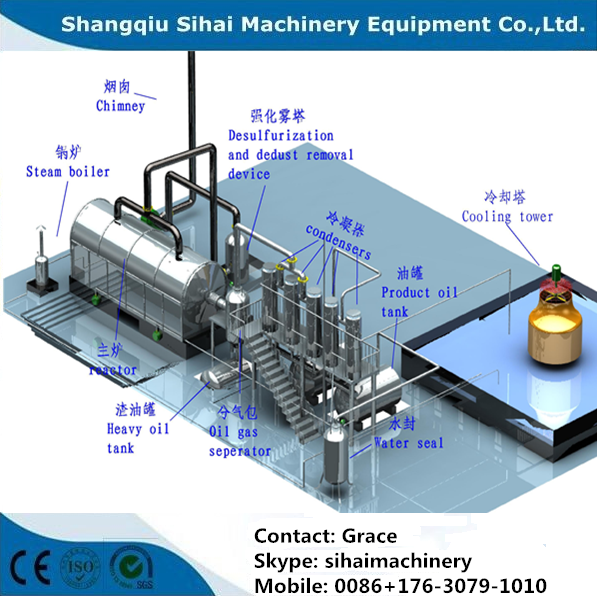

2. Working process Of waste plastic pyrolysis plant with 90% oil yield:

First, the raw materials are put into the reactor, and then seal the feeding in door, later start the machine and the reactor will be rotating and heated by coal, natural gas, wood or electricity. When the temperature reaches the degree of 250 to 280, we will get the crude oil, the oil steam will be continuous produced until the temperature reaches 350-460°C; oil steam will flow through oil gas separator, light component will enter the condensers and meanwhile the heavy oil will be discharged automatically into in heavy oil tank. The liquefied part will be condensed as crude oil, and the part which cannot be liquefied will be transferred by the water seal back to the burning chamber to be reused as heating material.

3. Raw material can be used and oil output reference:

RAW MATERIAL MAIN PRODUCT OIL OUTPUT PVC PIPES, CABLE SKIN,SOLE 40%-50% PE PIPES, WASTE PLASTIC BAGS,PLASTIC FILM,PACKAGE FILM 75% PP PIPES.CAR BUMPER,PLASTIC BUCKET,INJECTER 20% PS FOAM BOAD, THROW-AWAY LUNCH BOX 30% PET BEVERAGE BOTTLE, TAPE. 20% PP PLASTIC BOX, CUP,BOWL, 65% ABS COMPUTER SHELL, TV SET SHELL,PLASTIC DINNERWARE 40%

4. Installation: We will be in charge of arranging our engineer to go to your place to guide the installation and train your workers how to operate the waste plastic pyrolysis plant with 90% oil yield,and you will be in charge of the food, accommodation and round air tickets.

5. Land requirement: 300sq meters(10m*30m)

6. Exporting Experience:

America: Brazil, Canada, Colombia, USA, Middle East: Dubai, Iran, Jordan, Saudi Arabia, Turkey Europe: Albania , Bosnia and Herzegovina Asia: Afghanistan, India, Malaysia, Pakistan, Philippines, South Korea, Vietnam, Myanmar Africa: Ghana, Mozambique, Zambia

Product Categories : Waste Plastic Pyrolysis Plant

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.