Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LJ-8

Brand: SIHAI

Material Processed: Plastic Bottle

Plastic Type: PET

Automation: Automation

Computerized: Computerized

Certification: CE ISO SGS

Warranty: Life Long

Cooling System: Water Cooling

Heating Method: Direct Heating

Material: Q245R Boiler Steel

Oil Output Rate: 45%

Area Required: 300 Square Meter

Installation: Free Of Charge

Reactor Size: 2600*6600mm

Handling Capacity Tons: 10 Tons

Packaging: Seaworthy packing

Productivity: 200SETS/YEAR

Transportation: Ocean

Place of Origin: HENAN

Supply Ability: 200SETS/YEAR

Certificate: CE ISO

HS Code: 8419409090

Port: Lianyungang,Qingdao,Shanghai

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CIF

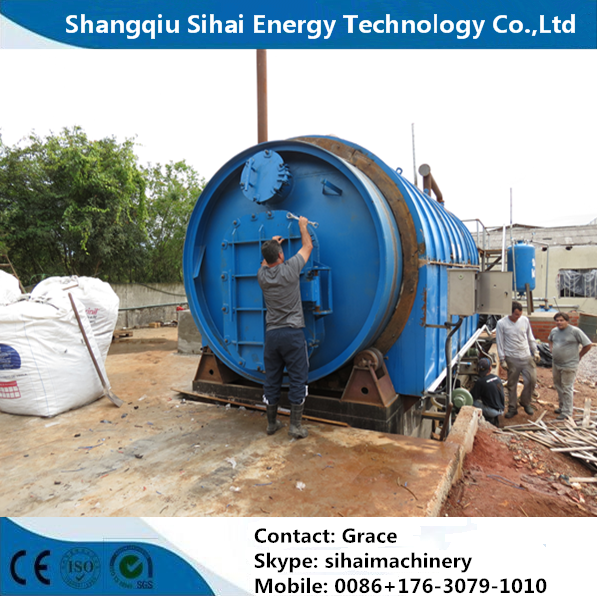

Fuel oil extraction machine by pyrolysis system

Features of Equipment:

a.In the design of pyrolysis key device,completely overcome the local heat uneven,easy to break,low yield,short life and other unfavorable factors of the current vertical flat bottom Pyrolysis Plant.

b.With fast and practical feed and slag system.

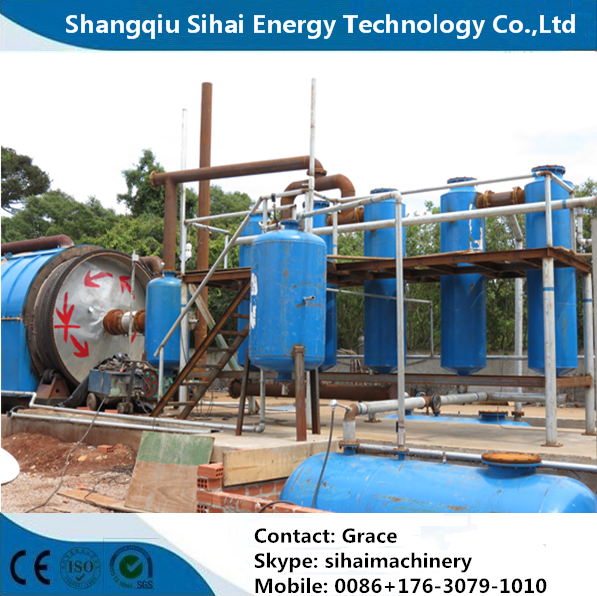

c.Efficient gas heating system.In the process of refining,when the heated gas reaches 150 degrees Celsius,it will produce a lot of gas which can not be liquefied in normal temperature and pressure methane to butane.These gases are fully burned by specially designed gas nozzles,will produce a lot of energy which greatly saves energy.

d.Flue dust removal system has a desulfurization dust cather(qualified),equipped with two ways water impact cyclone dust removal chamber,which can ensure the discharge of flue outlet reach safe discharge standard.

1. Model of Fuel oil extraction machine by pyrolysis system:

| Model | Reactor size | Material | Handling capacity | Weight | Seaworthy packing |

| LJ-8 | 2200*6000mm | Q245R boiler steel plate | 5 tons | 24tons | 2*40HQ |

| LJ-9 | 2200*6600mm | Q245R boiler steel plate | 8tons | 26tons | 2*40HQ |

| LJ-10 | 2600*6600mm | Q245R boiler steel plate | 10tons | 30tons | 1*40FR+1*40HQ |

2. Working process of Fuel oil extraction machine by pyrolysis system:

First, the raw materials are put into the reactor, and then seal the feeding in door, later start the machine and the reactor will be rotating and heated by coal, natural gas, wood or electricity. When the temperature reaches the degree of 250 to 280, we will get the crude oil, the oil steam will be continuous produced until the temperature reaches 350-460°C; oil steam will flow through oil gas separator, light component will enter the condensers and meanwhile the heavy oil will be discharged automatically into in heavy oil tank. The liquefied part will be condensed as crude oil, and the part which cannot be liquefied will be transferred by the water seal back to the burning chamber to be reused as heating material.

3. Raw material can be used in Fuel oil extraction machine by pyrolysis system and oil output reference:

RAW MATERIAL MAIN PRODUCT OIL OUTPUT PVC PIPES, CABLE SKIN,SOLE 40%-50% PE PIPES, WASTE PLASTIC BAGS,PLASTIC FILM,PACKAGE FILM 75% PP PIPES.CAR BUMPER,PLASTIC BUCKET,INJECTER 20% PS FOAM BOAD, THROW-AWAY LUNCH BOX 30% PET BEVERAGE BOTTLE, TAPE. 20% PP PLASTIC BOX, CUP,BOWL, 65% ABS COMPUTER SHELL, TV SET SHELL,PLASTIC DINNERWARE 40%

4. Installation: We will be in charge of arranging our engineer to go to your place to guide the installation and train your workers how to operate the Fuel oil extraction machine by pyrolysis system

Product Categories : Waste Plastic Pyrolysis Plant

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.